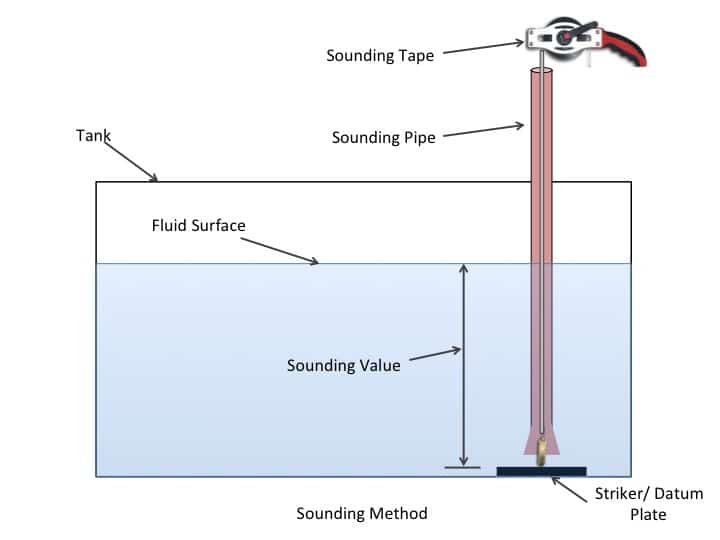

Ullage measurement using ullage equipment should be conducted as follows: Obtain approximate tank ullage using vessel ATG or other method. After safely grounding the tape and opening the gauge hatch, slowly lower the tape and bob into the tank until the bob just touches the. Ullage measurement using ullage equipment should be conducted as follows: Obtain approximate tank ullage using vessel ATG or other method. After safely grounding the tape and opening the gauge hatch, slowly lower the tape and bob into the tank until the bob just touches the surface of the liquid (see Figure 6). Tank Volume Calculator Select the style of tank and its dimensions to calculate the capacity. Optionally, enter the filled depth to calculate the volume of liquid in a tank.

Introduction

|

We have developed spreadsheet-based files that have customised cargo work calculations for a crude oil and product tankers. Our standalone products are designed for the business of shipping cargo (chemicals, oil or products) via shipping vehicles (tankers) or storing them ashore or in floating storage units (FPSO). We prefer to work with Microsoft Excel (images below are snapshots of Lotus 1-2-3 files).

The latest products are standalone with a backend database storing the manual entries for each port of call. The database can be used to produce all kinds of MLI statistical analysis.

Entries by user would be:

- Cargo Ullages and temperatures tank-wise;

- Fuel/FW Tks Qty;

- Interface sounding for free water, if any;

- OBQ/Slops on board, if any;

- Tables required (6, 24 or 54 A/B); (selectable by mouse click)

Make your own spreadsheets or standalone projects. Download theadd-in dll(s)with all the functions you need for the tanker industry.

The results are transferred to the following with tabulated and/or chart representations and may be printed at will

- Trim/Stability;

- Record of V.E.F. for last 10, 20 and 30 voyages;

- Charterer's and Owner's forms, viz. Letters of protest for BL discrepancies, delays, free water, port log, Ullage Report, Stowage Plan;

Hydrostatic calculation (draft survey) with hog or sag deflection is also included.

Customised menus allow macros to run for:

- Online registration of tank volumes where such hardware fitted, (We can undertake turnkey installation of hardware at dry-dock);

- Print;

- Backsolveto required - Nett MT, Barrels, DWT or Draft;

- A scratchpad for quick conversion from degrees F'ht to C, Ft to M and vice versa with resultant DWT for that Ft or M.

Also included is the extremely powerful and much used (by the Chief Officers), add-in calledSolver. Solver provides an optimal solution to various loading/discharging scenarios in a matter of seconds.

Example:

You have a nominated BL Qtty of 630,000 Nett Barrels of Oseberg Blend to load from Sture (Salt water) for discharge at Immingham (brackish). With the given bunker ROBs and load temperatures, draft restrictions, Solver can find a loading distribution to satisfy the given constraints which would be - no list, even keel arrival, volumes <= 98%, minimum stresses, etc.

We offer to write a similar customized spreadsheet for a fee, for any tanker operator/owner who may get in touch with us by e-mail for a sample spreadsheet at:

Top of Page

Trim & Stability

The following is a picture of the bottom half of the 'Trim/Stab' page in the Lotus Workbook. The unseen portion has the data for Provisions, Constant, FW, Ballast, Fuel / Diesel and Cargo.

KG, LCG and Inertia Moments are tabled for each and the results are displayed as seen below.

Results of the 'Stress' page are also incorporated.

An attempt is made to reflect the actual draft taking into consideration the deflection due to stresses vis-a-vis the straight girder theoretical results. This is useful in cases of sailing in shallow waters where the additional max. draft due to stresses must be taken into consideration, as too the squat.

Click on Image To Magnify It

Also calculated, is the loss of GM upon touching the blocks during dry-docking.

Top of Page

Return

Back Solve

You may select an item from the list above to backsolve to.

Example:

You may need to know, with the given the cargo API/Density and temperatures (which would be entered in the 'Ull Rep' page and the Constant / Fuel / FW / Ballast conditions (entered in the 'C Fuel FW B' page), and the OBQ ('Wedge' page) and Slops onboard ('SlopCert' page), what the cargo loadable would be for a 'Mean-Draft' of 12.192 M Sea Water?

Backsolver would obtain results for you in a matter of seconds.

The distribution of the cargo tank-wise with the resultant drafts, trim and list would not usually be satisfactory. For a satisfactory distribution, the user would Click on Image To Magnify It need to use the 'Solver' facility.

Nevertheless, Backsolver serves the important purpose of a quickfire answer to quickfire questions that are posed ever so often to the vessel by the charterers / brokers. The distribution (stowage plan) may be obtained more leisurely by using the Solver facility.

Top of Page

Return

Solver

Solver is an add-in feature that comes free with Excel (Tools menu). Solver is an Add-in for Lotus 123 and licenced by Frontline Systems. We provide this add-in.

In the problem above -

Tank Ullage Calculator Estimate

The set cell is 'AVG-ALL STRESS', which is a cell in the spreadsheet that represents the average of all the BM and Shear Forces. The demand is to 'MINIMISE' the stresses.

The Changeable (Variable) cells are 'CARGO GAUGES', which are the MMC Ullages in the table. Additional variable cells may be added, viz. Ballast Tank Gauges.

The constraints are many - (up to 100 constraints may be included in this part of the dialog box). The constraints not seen in the picture above are:

Click on Image To Magnify It

- Heel Moments = 0

- Nett Barrels = 631,890 (B/L nomination 630,000 * clean VEF of 1.003)

Solver should be able to come up with an optimal solution in a matter of minutes, if not in seconds.

In the example above, the results (solution), will provide a possible loading pattern keeping to the SetCell demand for a minimised average of all stresses, a cargo quantity of 631,890 Nett Barrels, No List, aft trim=0.2M, etc.

Any Chief Officer would be delighted to use this add-in and it would be redundant to point out that the cost of the add-in is well worth the time saved in this aspect of loading/discharging operations.

Top of Page

Return

Hydrostatic Calculation

Facility is provided to compute the weight of the cargo on board by hydrostatic calculations from the draft gauges as well as from the observed drafts at the draft marks.

Click on Image To Magnify It

Top of Page

Return

Sample Prints/Wkb Pages

Ullage Space

To list of a few -

- Stress Calculation Results

- Letter of Protest - Free Water

- Vessel Experience Factor

Make your own spreadsheets or standalone projects. Download theadd-in dll(s) with all the functions you need for the tanker industry.

Requirements

- Online hardware, if pickup of online data required

Top Of Page

Tank Ullage Definition

Additional Information

We have undertaken smaller projects too - Ullage reports only for crude and product tankers with results exported to charterer's and owner's standard forms (ship specific data for tank volumes with trim and heel correction, stability, stresses and hydrostatic calculations, etc. not included).

Tank Ullage Calculator Formula

- For Shipping Companies -Engine Department.